Roll Forming Corporation Improves Quality & Value with FEA Modeling

Advanced Software Facilitates Virtual Testing to Refine Tooling for Complex Parts

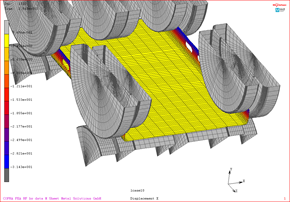

View of metal deformation as the strip progresses through consecutive passes of roll tooling

The Clients

Roll Forming Corporation manufactures custom and pre-engineered roll-formed profiles for a diverse list of clients throughout North America. These clients serve a wide array of industries including renewable energy, office systems, aerospace, material handling, agriculture, construction, transportation and other industrial products.

The Challenge

Many of Roll Forming Corporation's clients require complex parts to meet their application requirements. This level of complexity generates the need for highly engineered tooling design and set-ups. In order to launch a new profile or refine an existing one, multiple tooling trials have often been necessary to achieve precise quality standards. These tooling trials are costly in both machine downtime and dollars.

The Roll Forming Corporation Solution

By utilizing Finite Element Analysis (FEA) Roll Forming Corporation is able to virtually evaluate new tooling or refine existing tooling before part production. This allows more cost-effective management of product design, development, and fabrication. FEA essentially creates a virtual roll forming mill that can be used to carefully examine every part of the process—from each individual set of rolls to potential product deformity that tooling and material type might cause. In the hands of Roll Forming Corporation's experienced engineers, FEA can reduce the number of tool iterations during product development and weeks from manufacturing lead times. It enables Roll Forming Corporation to give clients tangible proof that a proposed solution to a design is viable offline, without the investment of unnecessary time and resources.

For example, when a material handling automation solutions provider wanted to improve the cosmetics of a computer rack-mounting system rail, Roll Forming Corporation was able to save the client time and money by creating an FEA model demonstrating a tooling change that would solve the issue (a small wrinkle around a mounting slot that became visible when painted).

Results

FEA allows Roll Forming Corporation to ensure the quality of the parts it makes in an efficient, cost-effective way by eliminating multiple tooling set-ups and trial production runs for "unproven" designs and modifications. This translates into enhanced value for the customer by saving both time and money.