Roll Forming Corporation is Tops in ROPS & FOPS

Custom and Standard Tube Designs Deliver Performance while Saving Clients Time and Money

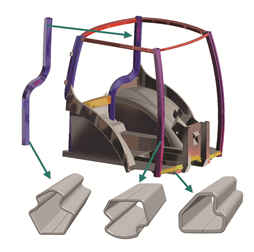

Cab model showing the functionality of ROPS & FOPS tubes

The Clients

Roll Forming Corporation is the largest custom tube manufacturer for rollover protective structures (ROPS) and falling object protective structures (FOPS) in North America. It is known throughout the industry as the provider of choice for the most well-known manufacturers of construction, agricultural, and material handling equipment. Makers of recreational all-terrain vehicles also partner with Roll Forming Corporation for their ROPS and FOPS needs.

The Challenge

ROPS and FOPS are essential for the safety of construction, agricultural, and material handling equipment operators, as well as for drivers of all-terrain vehicles. There are strict regulations in place (established by government entities) that all manufacturers must follow in order to sell their products both domestically and internationally. So, while all manufacturers need to have quality structural tubing for their equipment, for many of them, the resources and operational logistics of producing these components in-house are cost prohibitive. To cost-effectively meet their ROPS and FOPS requirements, they partner with Roll Forming Corporation.

The Roll Forming Corporation Solution

To satisfy clients' ROPS and FOPS needs, Roll Forming Corporation offers a variety of standard and customized tubes with material thicknesses ranging from 2mm to 4mm. In its Indiana facility, Roll Forming makes four different section types on a state-of-the-art production line featuring 1,200 to 2,000 individual pieces of tooling that change depending on the model being produced. The four sections are: "A" posts, "C" posts, door sections, and window sections. All components can be modified to client specifications with secondary tooling and processing operations like bending, sawing, laser cutting and hole-punching. Benefitting from over 35 years of ROPS and FOPS component manufacturing experience held by its European parent company, voestalpine AG, Roll Forming's clients enjoy the advantages of tube designs that have been field-proven time and time again.

Results

ROPS and FOPS solutions from Roll Forming Corporation enable manufacturers to provide quality, high-performance products to their customers while saving time and money by eliminating the need for additional in-house resources.